Machine Learning As Well As Robotics Are Helping Solve The Plastics Sorting Problem.

There are 12 billion tonnes of plastic throughout landfills by 2050 if current trends continue. It’s the equivalent of the weight of the Empire State Building 35,000 times over. What else can be used as a rallying cry?

Only 4% of the world’s population resides in the United States, but that country generates more waste per capita than any other, at 14%. Over 36 percent of the world’s population and 27 percent of the world’s waste is generated by India and China. ” U.S. needs help disposing & reusing waste to make things even worse. Chris Wirth, AMP Robotics’ Vice President of Marketing, estimates that 90 million tonnes of highly recyclable products have been thrown away each year and sent to landfills.

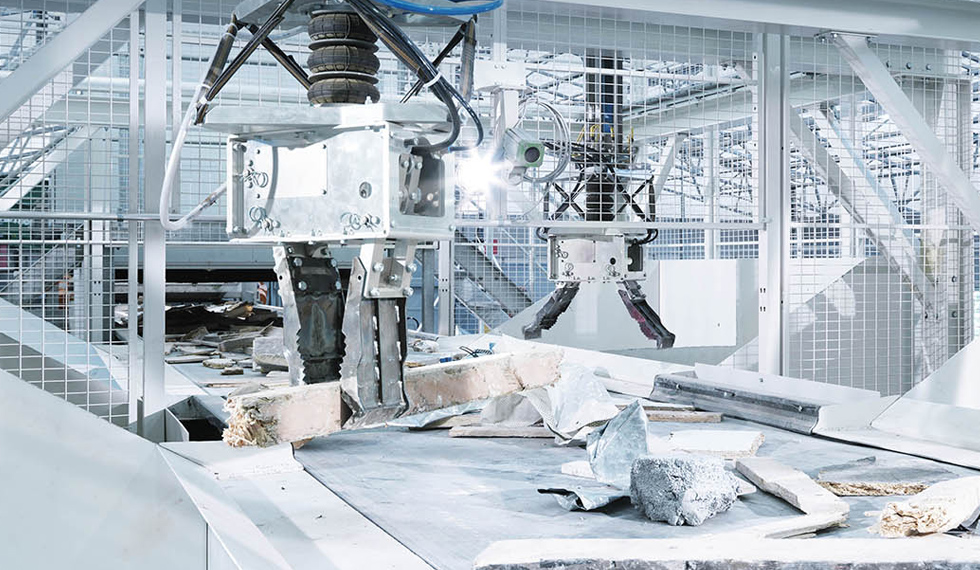

Using Robots To Perform Sorting Is A Viable Option

Artificial intelligence & robotics are combined to automate the sorting of recyclable plastics, saving time and labour costs that would otherwise be borne by humans. As a result, these companies are using robots to sort recycling and eliminate any health risks associated with human labour by using advanced cameras and technology. Researchers at University of Chicago Department of Public Health found that recycling workers have a workplace injury rate that is two times higher than the average.

What Is The Process Of Robotic Recycling?

Automated guidance systems, such as cameras and sophisticated computer systems, will direct robot arms over conveyors in order to reach their intended destination accurately. Recyclables can be snatched out of the trash by oversized fingers to sensors attached to their arms, which then place people in their designated bins.

However, companies have discovered that recycling robots can work 2 times faster than humans. In order to make waste sorting easier, industry leaders had also developed robots that really can distinguish between plastics of varying colours, textures, shapes, & sizes in real time.

In some cases, the resale value of a product can be doubled by using this method. Firms are scrambling to come up with reliable solutions as quality standards rise. It’s a race against time for one city to get ahead of the curve. At this rate, San Francisco will be the first American city to achieve zero waste. An $11 million upgrade to Recology’s plant just on San Francisco Bay has just been completed, and the company plans to invest an additional $3 million in high-tech optical sorter robotics this year.

Advantages Of Sorting By Robots

Robotic Recycling Has A Number Of Advantages, Such As:

Materials recovery facilities all across United States find it difficult to hire and retain workers, which is one reason for reducing reliance on manual sorters. The 1.5 workers takes to pull cartons off the connection can be replaced by an AI-powered robot. They can then be transferred to other areas that need their attention, which will speed up the process.

A camera is used to inspect each product as it comes off the line, and data accumulated over time is used to predict where it would go next. This also implies that the robots’ data on materials can be continuously updated and added to, which is beneficial in the long run. In the near future, robots could be able to make all of the necessary adjustments under their own, thanks to advances in artificial intelligence (AI).

For the first time, we’ve learned how optical sorters work. Over time, this will lead to a greater understanding of the types of materials that come in how people differ from one another. Other plants from across country that use robotic sorting methods could also benefit from the information.

Data storage and processing will be much faster thanks to AI-powered robots. The larger recycling community can then use this information to improve their own output.

Automated sorting of plastics: Robots can ensure faster, more precise, and better-quality sorting of plastics. Plastic waste will also be reduced as a result of this change. Speed and accuracy in the “hands” allow for greater output.